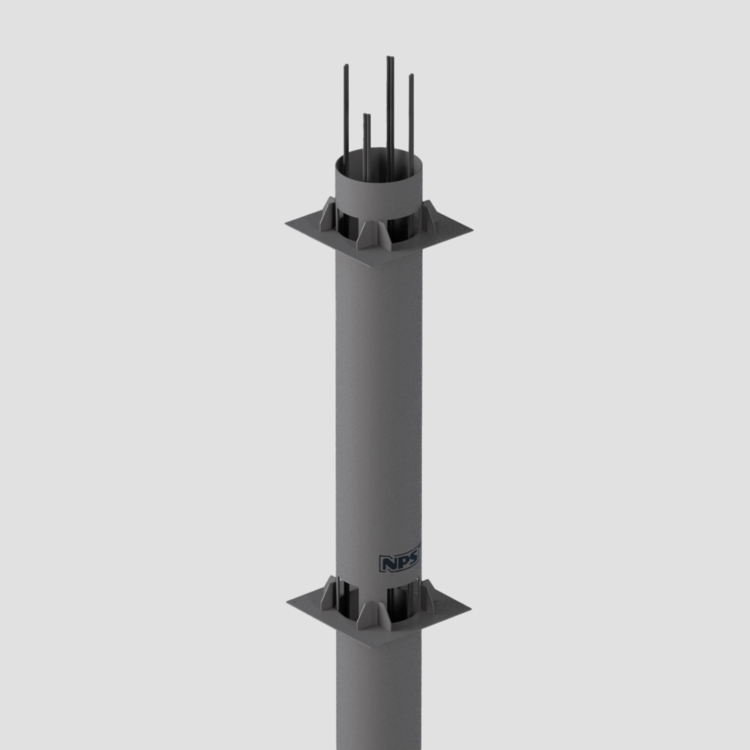

NPS® Slim Column

NPS® Slim composite columns are steel columns marked CE EN1090-1.

They are filled with concrete after installation on site. They provide native fire resistance, without the need for additional work on site, thanks to the internal reinforcement cage. They offer high load-bearing capacities and compact cross-sections.

Also suitable for construction in seismic zones due to the ductility of the structure. Suitable for multi-storey buildings such as hospitals, hotels, shopping centres, residential buildings as well as infrastructure.

The NPS® Slim column is available with a circular, square or rectangular cross-section. Unlike traditional reinforced concrete columns, the round and compact shape allows for more space and therefore more options. It can be supplied in a multi-storey version, also with a differentiated cross-section for each inter-storey. By installing a three-storey NPS® Slim column, you already have the vertical element for the two upper storeys ready: a considerable time saver.

Benefits

- Native fire resistance

- Compact sections

- High load capacities

- Seismic-resistant solution without bracing

- Quick and easy to assemble

- Available in multi-storey version to speed up assembly

- Construction site safety

Areas of use

- Industrial building

- Civil construction

- Tertiary

- Accommodation facilities

- Hospital facilities

- High buildings

- Infrastructure

- Renovations

- Elevations

Application-Technique Recommendations

PDTI® NPS® steel columns perform well in both frame and wall buildings. Beam support flanges are easily adaptable even in cases of height differences and non-perpendicular beams.

Ing. Alessandra Favarato, NPS® designer

Fast return on investment

- Reduction of the building construction time of at least 40% compared to traditional systems, ideal for new buildings or renovations.

- Certain costs.

- Irrelevance of weather conditions to the execution of the work.

- Low maintenance costs.

Efficient and safe solution

- Laying speed: 8 minutes for a multi-storey column, 5 for a beam.

- Reduction of 80% of labour requirements on site.

- Increased safety on site.

- Almost total elimination of props on site.

- Delivery of beams, columns and slabs at the time of installation, without the need for storage space.

Reduced environmental impact

- Enviromnental Product Declaration (EPD), contribution to obtaining LEED and DGNB credits and compliance with CAM.

- Up to 93% recycled steel content.

- Lower use of raw materials compared to traditional systems, with the same performance.

- 90% less temporary material on site, with positive effects on costs and waste.

- Lower energy consumption and lower CO2 emissions than steel and reinforced concrete solutions.

- Proven environmental impact per kg of product demonstrated through Life Cycle Assessment (LCA)

Seismic and native fire resistance

- Native fire resistance, without the need for treatments after installation. A saving in terms of costs and time.

- Native seismic resistance, no need for bracing.

- Consolidated experience of Tecnostrutture in the seismic field.

- NPS® elements can also be used as visible architectural elements without the need for additional treatments.

High structural flexibility

- Maximization of usable space in width and height thanks to beams with large spans and thin pillars and floors.

- Customization of NPS® beams.

- Flexibility in the distribution of interior spaces, with ease of layout change over time.

- Standard spans up to 15 meters. Longer lengths are also possible, following due analysis.

- Maximum storey height thanks to slim-floor solutions.

Design in BIM with PDTI® pillars for Tekla and Revit

PDTI® columns’ parametric objects for Revit and Tekla are a tool to speed up design and make the engineer's job easier.

DOWNLOAD OBJECT FOR REVITDOWNLOAD OBJECT FOR TEKLA

Certified environmental impact

For each specific project, the environmental impact of the NPS® solution can be calculated in terms of CO2 equivalent and numerous other indicators, based on the official Environmental Product Declaration (EPD). This allows the planner and investor to compare the environmental impact of alternative structural solutions and make an objective choice.

The NPS® beam-pillar solution reduces CO2 emissions and energy used by more than 20% compared to steel or concrete solutions. These data are proven by the comparative LCA carried out by the University of Genoa on two actual buildings. The environmental impacts per kg of beam are confirmed by the Environmental Product Declaration (EPD).

DOWNLOAD THE EPD OF THE PDTI® NPS® COLUMNThe importance of embodied carbon

Until now, the focus has been on reducing the emissions produced during the use of the building.

However, it is estimated that more than half of the total carbon emissions from all the new global constructions between 2020 and 2050 will be due to embodied carbon and therefore emissions related to materials and building construction/renovation (source BuildingLife Roadmap).

It is therefore necessary to focus not only on the operational emissions of buildings and to start considering both operational and embodied carbon in an integrated way.

NPS® beams represent an economic, fast and at the same time sustainable structural solution.

Contributes to obtaining LEED and DGNB credits

The use of NPS® beams can contribute to credits for building sustainability certification.

An external body supported Tecnostrutture in conducting a mapping on the contribution of NPS® products for obtaining credits for building sustainability certifications.

These specific mappings are available for LEED and DGNB certification.

DOWNLOAD LEED MAPPINGDOWNLOAD DGNB MAPPING

Lower raw materials

PDTI® NPS® Columns take advantage of the structural efficiency of combining steel and concrete. This results in compact sections with less use of raw materials and optimization of living space.

Made with recycled steel

PDTI® NPS® columns are made from recycled steel, accounting for 16% of the total weight, as confirmed by the Environmental Product Declaration (EPD) issued by a third party.

The declaration is based on Life Cycle Assessment (LCA) per kg of pillar.

Logistics with low environmental impact

Tecnostrutture adopts a logistics strategy that respects the environment. We prefer green fuel road transport or the intermodal solution with longer stretches by rail.

As shown by the analysis of the product life cycle (LCA), transport to the construction site affects 2-3% of the total life cycle. Therefore, in addition to offering solutions that have little impact on logistics, Tecnostrutture’s commitment focuses above all in the raw material supply and end-of-life management phases, those that weigh most heavily on the environmental impact of the entire product life cycle.

Reduced emissions throughout the life cycle

- The pillars are modelled in BIM, with the lowest possible use of raw materials from the outset.

- They are produced in the factory using both self-generated energy and - as of January 1, 2022 - energy derived entirely from renewable sources.

- Logistics is also low emission. Tecnostrutture gives priority to green-fuel and intermodal transport.

- Site organization is simplified thanks to the fact that fewer workers are needed for assembly: a team consists of just three fitters and a crane operator, compared to the large work teams of traditional systems.

- Reducing on-site activities increases construction speed by an average of 40%, with positive social effects on the local community.

- There are also advantages in relation to the drastic reduction of formwork, wood and props that are no longer necessary since the structures are self-supporting. This saves trips to bring in and return the temporary materials as well as their production. The result is a substantial contribution to the reduction of construction site waste and scrap, with NPS® products arriving ready for assembly.

- At the end of the building's life, NPS® beams are removed through selective demolition, which allows for the reuse of the steel and concrete used.

Storage

NPS® pillars are designed to be assembled directly from the transport vehicle. If storage is the option, they can be stacked horizontally up to 4 levels and 3 meters high, resting on wooden planks.

For long-term storage, steel structures must be covered.

Each NPS® column is marked with an identification tag that shows the code as shown in the drawing.

For technical storage requirements, please refer to Tecnostrutture’s product assembly and installation booklet.

Handling

The internal route through the site and the material storage area are agreed with the site manager.

NPS® columns can be lifted and handled with normal lifting equipment, such as cranes or crane trucks. The weight of each structural element is indicated in the manufacturing drawings.

For technical handling instructions, please refer to Tecnostrutture’s product assembly and installation booklet.

Installation

- Normally, from lifting to fixing, a multi-storey NPS® column is installed in 8 minutes with a team of three workers and a crane operator.

- Before installing the columns, prepare the anchor bolts fixed to the support surface, laid using the templates supplied according to the axes and dimensions of the project.

- Screw the lower nuts with the washers on them up to the required height.

- Lift the column with the crane and position it by inserting it on the anchor bolts placed at the base of the project support surface.

- With the lifting device in traction, tighten all nuts, preceded by their washers.

- Once the fixing to the base is assured and the base verticality is guaranteed, loosen the device.

- Pull the release lanyard until the pin is completely out of the hole or window in the column.

- At this point the final plumbing is completed.

- The pillar base is then fastened with anti-shrinkage pourable mortar. The thickness is given by the distance between the laying surface and the base plate of the pillar itself.

- We then move on to the integrative casting of the column.